Shaping your future

Sustainable Optimisation of your processes

Process optimisation for time and cost savings

Whether you are a manufacturing company, a craft business or a service provider, we will find practical and efficient solutions to your problems.

With our help, you can save valuable time in your daily work or reduce the costs of your processes.

What optimisation would you like to pursue?

Optimisation of business processes

efficiency increase

with digitalisation

Ensuring your

competitiveness

How do we work?

Analysis of current situation

An honest assessment of your current situation is the first step towards optimisation.

Identification of gaps and potentials

Through structured analysis, we identify weaknesses and hidden potential that will make your processes more efficient and future-proof.

Implementation and maintenance

Together, we will implement the optimal solution in your system and, of course, provide support to ensure that everything runs smoothly in the long term.

What our customers say

⭐⭐⭐⭐⭐

“Dr Walter Kähm is driving digitalisation in industry forward at an impressive pace. Particularly in the chemical industry, he combines in-depth technical expertise with innovative automation solutions. His know-how and strategic vision make him an indispensable partner for companies looking to take their processes to the next level.” – WeSaveIT

⭐⭐⭐⭐⭐

“I would like to warmly recommend Dr Walter Kähm from KDS. He developed an email bot for us that allows us to send our offers to customers completely automatically. What makes it special is that I can quickly make adjustments via WhatsApp without having to log into the system myself.

All new customers are automatically sorted into the CRM and the quotes are filed correctly straight away. This not only saves time, but also ensures that everything is properly documented.

This solution even enabled us to compensate for the resignation of a temporary employee – the tasks are now handled entirely by the bot.

For me, Walter is not only technically strong, but also someone who understands the processes in the company and builds solutions that really work in everyday life. The collaboration was uncomplicated and reliable – and the result has made our work much easier.

I can therefore recommend him without reservation.” – SorglosZuhause.com

⭐⭐⭐⭐⭐

“Dr Walter Kähm has given me a very good insight into the topic of automation and AI solutions.

His strategic expertise and technical knowledge make him an important asset for large companies.

I can highly recommend him.” – Marc Lombardo-Messinger

Successfully completed optimisation projects in industry

> 1 Mio€ cost savings without CAPEX

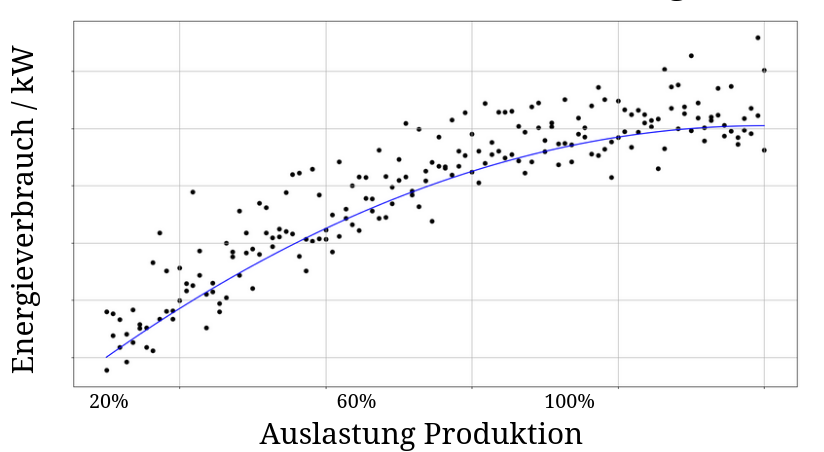

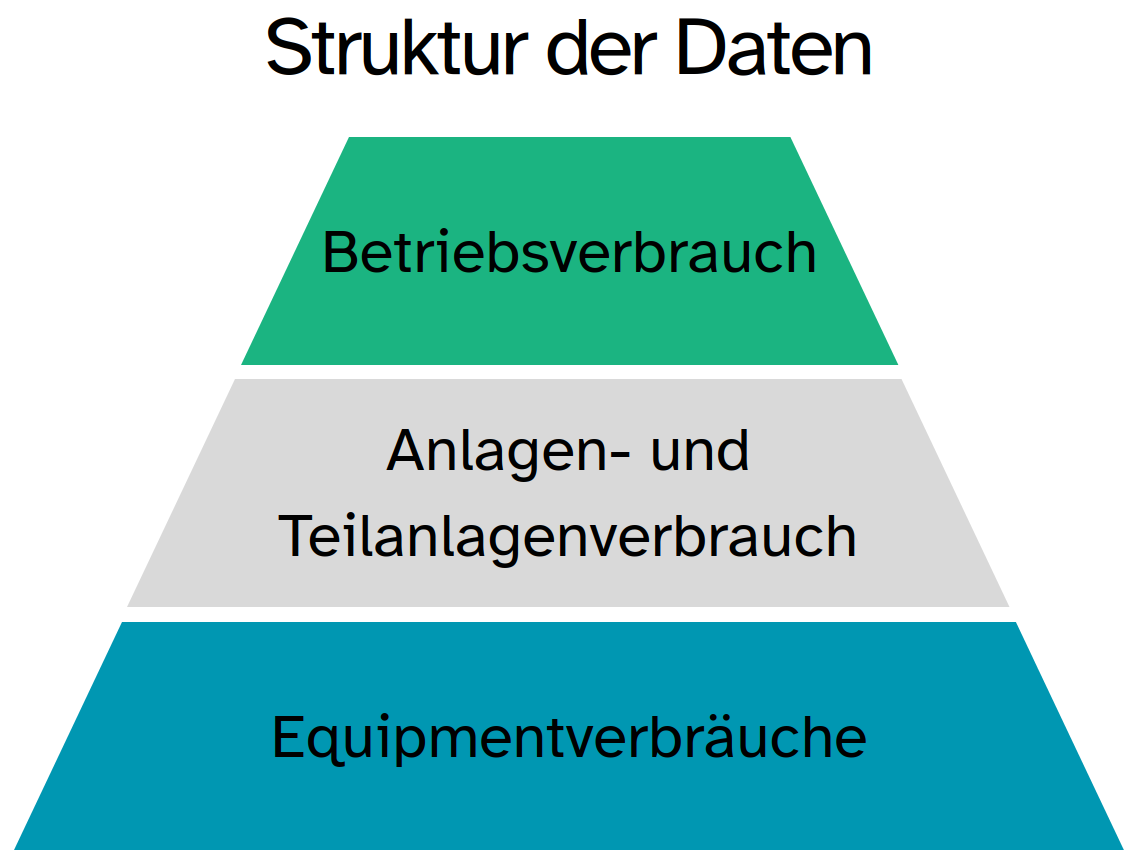

Through the use of intuitive data visualisations, AI evaluations and collaboration with operating personnel, energy savings of over €1 million have been achieved in chemical plants.

Involving all relevant individuals with practical expertise is essential for defining the right KPIs and developing dashboards that can be understood by everyone.

These projects are real-life examples of the statement ‘data is the new gold’.

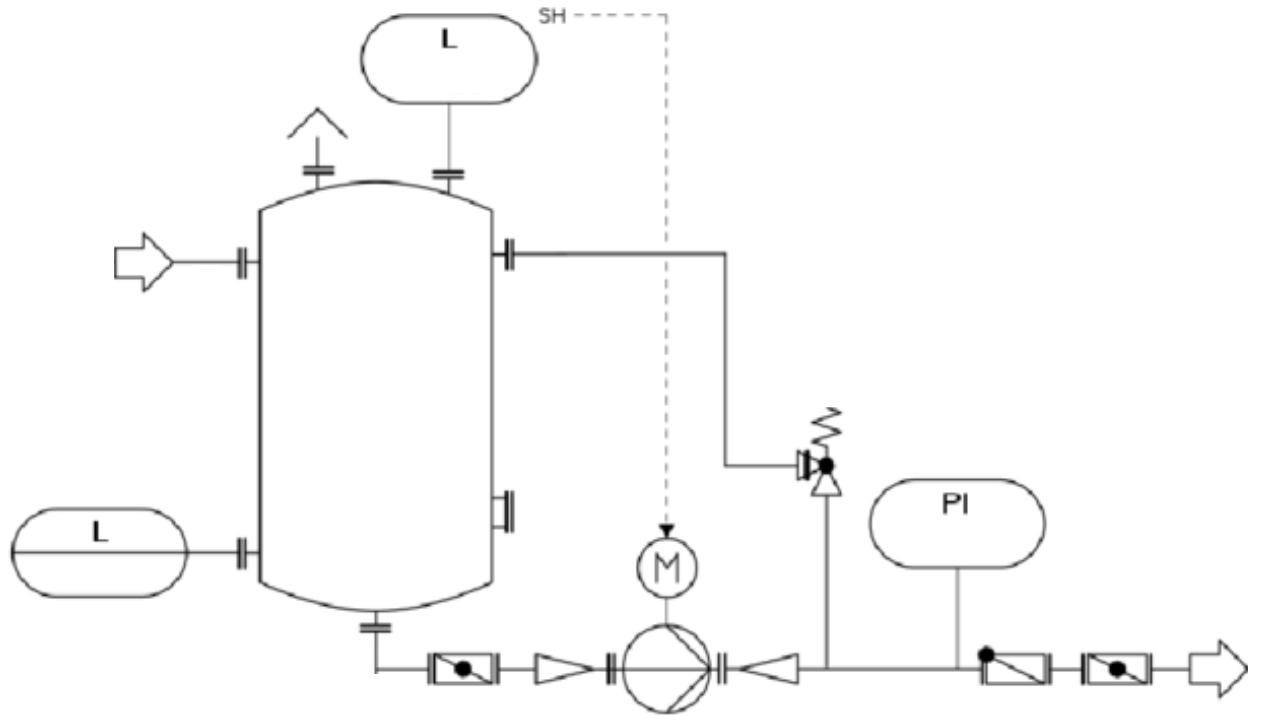

Avoid bad investments with first-principles models

The design of production facilities requires a sound basis for decision-making.

The weak point of data-driven models is extrapolation into unknown data spaces. Thermodynamics-based simulation models allow testing of production conditions that may never have been operated before.

These models have already prevented a number of bad investments and saved several hundred thousand pounds.

Better understanding of processes through digitalisation

Data, data, so much data… But what to do with it?

Structured processing and visualisation of process data can provide insights into ongoing processes that really save money.

From unexpected plant conditions of certain equipment (predictive maintenance) to an automated ISO 50001 dashboard with all energy and waste heat flows.

We create the data basis for you so that you can achieve this.

Business process optimisation

Increase your

efficiency

Ensuring

competitiveness

Successfully completed time-saving projects

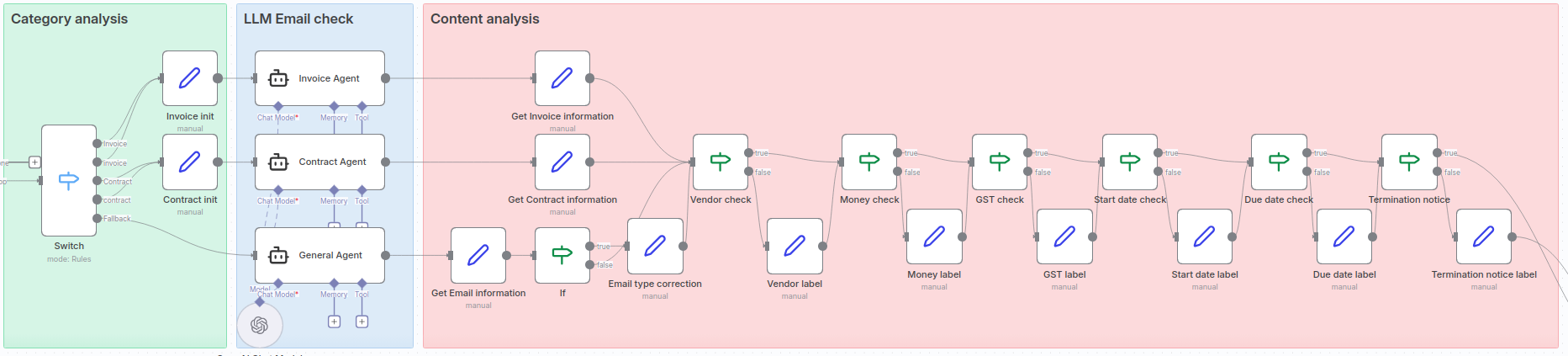

Save 10 hours per week with email automation

Do you have recurring tasks that feel like they need to be done 100 times a day? Responding to the same emails, sending out quotes, answering customer questions about the current processing status?

Automated workflows and AI can save a lot of time. Automated quote generation saves customers up to 10 hours per week.

No matter which CRM, ERP, or email solution you use, they can be tapped into and securely automated. In addition, individual solutions for your project, such as Python, can be integrated.

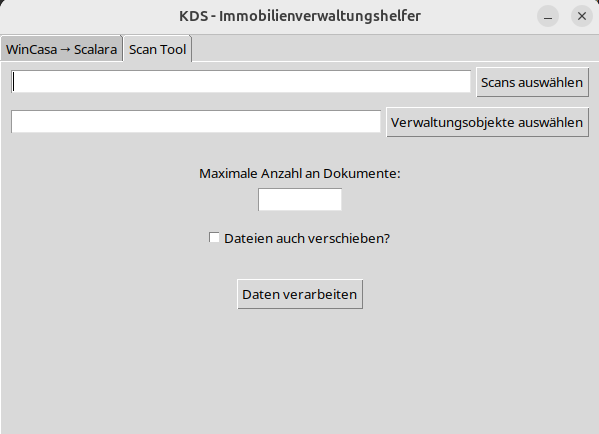

Save 2 hours per week with automated document management

Are you tired of scanning paper documents and manually filing them in the right folders?

With automated OCR tools, documents can be moved directly to the right folders after scanning and/or uploaded to the CRM or ERP system of your choice.

The rules and logic for where everything should go are customised and provided for you, so you can get back to focusing on your work.

Listen . Find Solutions .

You would like to advance digitalisation in your company? Arrange a meetingDr. Walter Kähm

I am a digitalisation consultant for industrial processes from Bonn. Even during my PhD in chemical engineering, I was fascinated by solving process engineering challenges with the help of digital tools and machine learning, a discipline of artificial intelligence. In the course of my professional life in the chemical industry, I have gained extensive experience – both in identifying sustainable solutions and in approaches that offer no added value in practice.

Theory and practice perfectly combined

A sound understanding of the current state of the art is essential in order to remain competitive. But theory alone is not enough – it must be supplemented with practical, process engineering expertise. This is the only way to develop sustainable and efficient solutions.

Over the past eight years, I have worked intensively on the successful implementation of digital solutions in the areas of production, logistics and management. My approach: information must be prepared and communicated in a way that is appropriate for each target group. I find it particularly exciting to find the optimal combination of tool, visualisation and infrastructure for each individual situation.

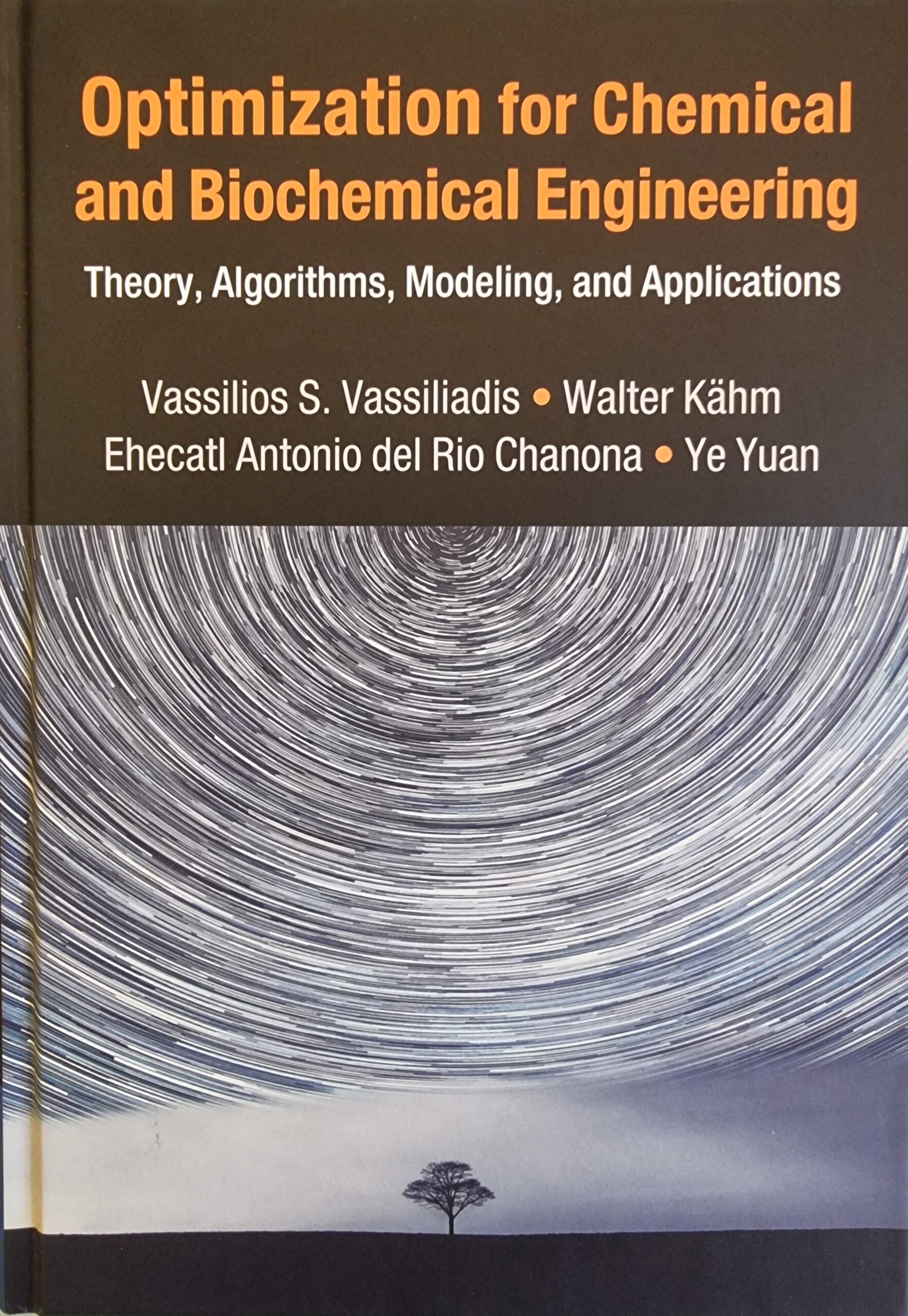

Optimization for Chemical Engineering and Biochemical Engineering –

Theory, Algorithms, Modeling and Applications

Cambridge University Press, Oktober 2020

During my PhD I had the privilege to work on the publication of this book. This work gives an overview of optimisation methods for various problems in the chemical and biochemical industry.

This book combines over 50 years of experience in the successful application of mathematical methods to industrial problems.

More information can be found here.

Book reviews

‘This book offers a very clear, uncluttered presentation of key ideas of optimisation in rigorous form and with plenty of examples from a decade of research and educational experience. It offers an exceptional resource for educators and students of optimisation methods, as well as a valuable reference text to practitioners.’

Alexei Lapkin – University of Cambridge

‘This excellent book brings together important and up-to-date elements of the theory and practice of optimisation with application to chemical and biochemical engineering. It’s an ideal reference for students on advanced courses or for researchers in the field.’

Nilay Shah – Imperial College

Contact form

Get in touch

We support companies with process optimisation and automation to increase their competitive advantage and boosting profits.